Product Description

Product Introduction

S&S double-wall tanks consist of an inner shell (6mm - thick steel plate) and an outer shell (4mm - thick steel plate). Meanwhile, a 4mm gap is created between the two shells for leak detection. S&S double-wall tanks are mainly used in open-yard scenarios. Their double - wall steel plate structure can withstand impacts. They can also be supported by leak detectors and other auxiliary equipment to ensure tank security

Standards for Product Implementation

GB50156-2012 Specification for design and construction of gas stations NB/T47003.1-2009 steel welded normal pressure vesselJB/T4709-2007 regulations of steel welded pressure vessel GB985-2008 basic form and size of air welding, manual welding, gas welding and weld groove

JB4730-2005 Nondestructive Testing of pressure vesse!NO. 66 Standars for about FPR double layer tank application by Japan Fire Depart-ment

UL-58

UL-1476

Product specification

|

Nominal capacity |

Diameter |

Tank Length |

Anchor number |

Band number |

|

20 |

2400 |

5053 |

2 |

2 |

|

30 |

2400 |

7080 |

4 |

4 |

|

30 |

2600 |

6192 |

4 |

4 |

|

40 |

2600 |

8050 |

4 |

4 |

|

40 |

2800 |

7190 |

4 |

4 |

|

50 |

2600 |

10100 |

6 |

6 |

|

50 |

2800 |

8700 |

4 |

4 |

Process introduction

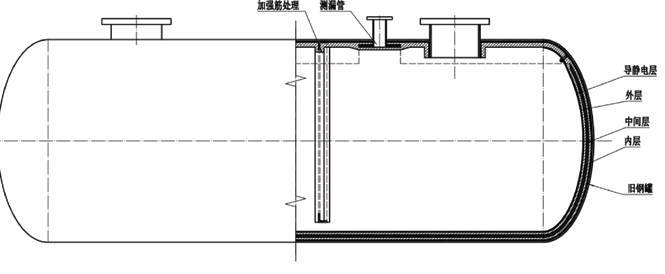

Oil tank anti - seepage renovation is an inner - lining modification technology. A double - layer glass fiber - reinforced inner lining is directly fabricated on the inner surface of the original single - layer oil tank. It consists of three layers: inner glass fiber - reinforced plastic, middle gap layer, and outer glass fiber - reinforced plastic, with a total thickness of 11–15mm.

After structural strength calculation and lay - up design, the renovated double - layer glass fiber - reinforced plastic inner lining replaces all functions of the original steel oil tank. It serves to bear loads, store oil products, and resist corrosion.

Renovate the structure

The inner, middle and outer structures ofthe oil tank seepage prevention modifica-tion are all made of fiberglass. The "outer layer" in contact with the oil product is amultilayer structure with conductive electrostatic layer, resin rich layer and struc turalayer etc.;, while the "inner layer" in contact with the original steel tank is a multilayerstructure with bonding reinforcement layer, resin rich layer and struc tural layer. Theintermediate test layer is between the "inner layer" and the "outer layer". The wholelining structure is made of spray and hand molding technology.

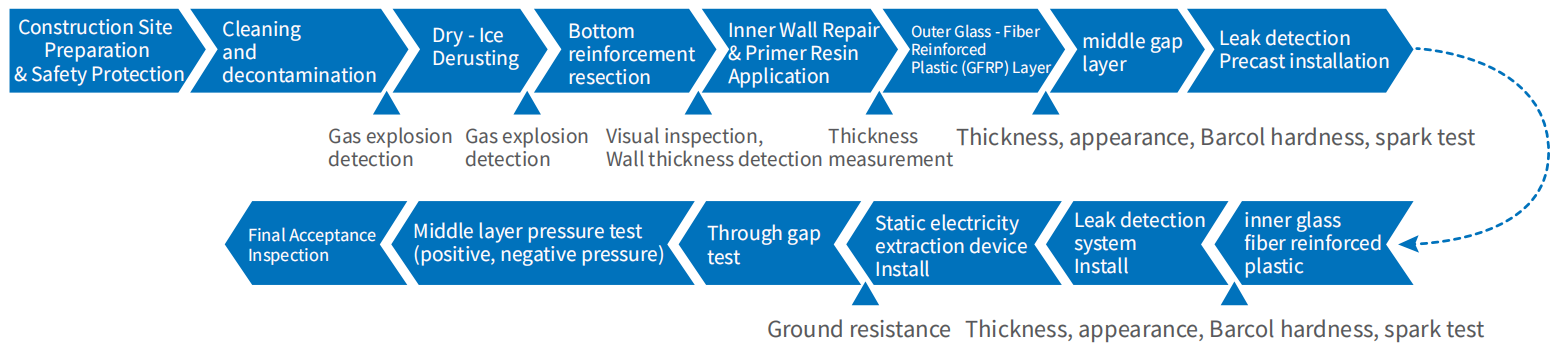

Flow chart

S&S Double-wall Tank

Get in touch for more information or to arrange a demo:

Products Category

Product Description

Product Introduction

S&S double-wall tanks consist of an inner shell (6mm - thick steel plate) and an outer shell (4mm - thick steel plate). Meanwhile, a 4mm gap is created between the two shells for leak detection. S&S double-wall tanks are mainly used in open-yard scenarios. Their double - wall steel plate structure can withstand impacts. They can also be supported by leak detectors and other auxiliary equipment to ensure tank security

Standards for Product Implementation

GB50156-2012 Specification for design and construction of gas stations NB/T47003.1-2009 steel welded normal pressure vesselJB/T4709-2007 regulations of steel welded pressure vessel GB985-2008 basic form and size of air welding, manual welding, gas welding and weld groove

JB4730-2005 Nondestructive Testing of pressure vesse!NO. 66 Standars for about FPR double layer tank application by Japan Fire Depart-ment

UL-58

UL-1476

Product specification

|

Nominal capacity |

Diameter |

Tank Length |

Anchor number |

Band number |

|

20 |

2400 |

5053 |

2 |

2 |

|

30 |

2400 |

7080 |

4 |

4 |

|

30 |

2600 |

6192 |

4 |

4 |

|

40 |

2600 |

8050 |

4 |

4 |

|

40 |

2800 |

7190 |

4 |

4 |

|

50 |

2600 |

10100 |

6 |

6 |

|

50 |

2800 |

8700 |

4 |

4 |

Process introduction

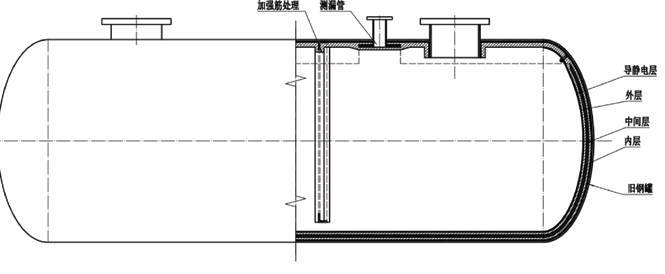

Oil tank anti - seepage renovation is an inner - lining modification technology. A double - layer glass fiber - reinforced inner lining is directly fabricated on the inner surface of the original single - layer oil tank. It consists of three layers: inner glass fiber - reinforced plastic, middle gap layer, and outer glass fiber - reinforced plastic, with a total thickness of 11–15mm.

After structural strength calculation and lay - up design, the renovated double - layer glass fiber - reinforced plastic inner lining replaces all functions of the original steel oil tank. It serves to bear loads, store oil products, and resist corrosion.

Renovate the structure

The inner, middle and outer structures ofthe oil tank seepage prevention modifica-tion are all made of fiberglass. The "outer layer" in contact with the oil product is amultilayer structure with conductive electrostatic layer, resin rich layer and struc turalayer etc.;, while the "inner layer" in contact with the original steel tank is a multilayerstructure with bonding reinforcement layer, resin rich layer and struc tural layer. Theintermediate test layer is between the "inner layer" and the "outer layer". The wholelining structure is made of spray and hand molding technology.

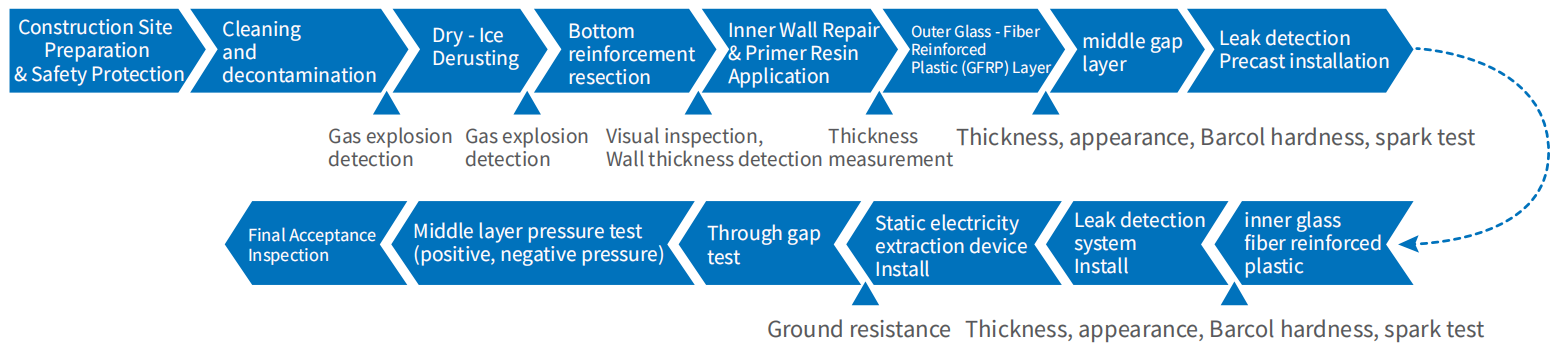

Flow chart

Get Product Information For Free

Note: Please leave your email address, our professionals will contact you as soon as possible!

Language

Language