Product Description

Product Introducticn

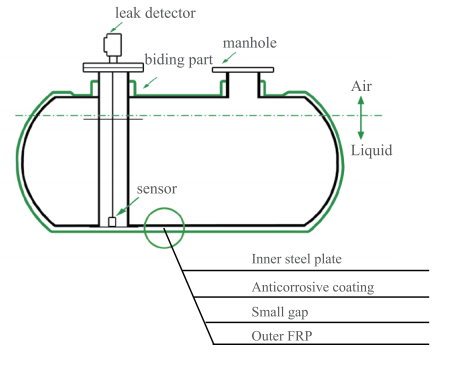

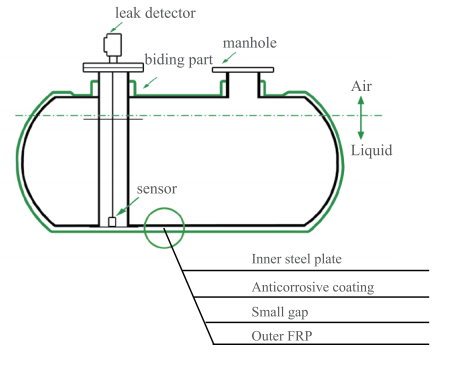

The main steel body of S&F Double-layer tank (with the full name of "steel reinforcedfiber-glass double-layer tank") is called "inner shell", and the FRP protective anddetecting layer

is called "outer shell".When S&F Double-layer tank is buried under.round,inner shell endures the pressure from earth and stone mainly. Although outerpressure acts on outer shell directly, it transfers to the inner shell synchronously.Therefore,the outer shell isn't the main part to keep the structural strength.

Standards for Product Implementation

♦ GB50156-2012 Design and construction standards of automobile gasotine and gas refueling station

♦ NB/T47003.1-2009 steel welded normal pressure vessel

♦ JB/T4709-2007 regulations of steel welded pressure vessel

♦ GB985-2008 Basic Forms and Sizes of Grooves for Arc Welding, Gas Welding and Gas Cutting

♦ JB4730-2005 Nondestructive Testing of pressure vessel

♦ UL-58

♦ UL-1476

Product Specification

|

Standard volume |

Diameter |

Tank length |

Anchor number |

Band number |

|

20 |

2400 |

5053 |

2 |

2 |

|

30 |

2400 |

7080 |

4 |

4 |

|

30 |

2600 |

6192 |

4 |

4 |

|

40 |

2600 |

8050 |

4 |

4 |

|

40 |

2800 |

7190 |

4 |

4 |

|

50 |

2600 |

10100 |

6 |

6 |

|

50 |

2800 |

8700 |

4 |

4 |

Product Structure

S&F double-wall product structure

Safety

Inner layer-double layer structure manufacturing, compared with the regular 5mm thickness single layer tank, the strength is greatly improved.

Outer layer- A reinforced glass fiber layer with a thickness exceeding 2.5m,featuring excellent crush and seismic resistance. It also has high corrosion resistance and electric erosion resistance.

Unique technology is used to create a 0.1m gap between the inner and outer layers and eliminate the hidden trouble from the root.

Advanced leaking detector 24-hour real-time monitoring to eliminate the hidden security risks caused by leakage.

Environmental Protection

Double-layer structure, with 0.1mm gap inside, the outer FRP ensures that the leakage material will not directly leak and pollute the soil and water.

The outer FRP will not cause electrolytic corrosion with groundwater,brine,etc.

The outer FRP will not corrode with gasoline,diesel oil and leaded gasoline.

Leak detectors provide 24/7 monitoring to eliminate potential pollution hazards.

Leaking detection system is easy to detect and maintain, protects the ecological environment of soil and water.

Effective protection of the environment, avoiding the high environmental protection cost.

Economy

The service life ofSF double-deck tank is 5-10 times of regular tanks, which can guar-antee safe service for at least 30 years.

Convenient installation greatly shortens the construction period and reduces cost input.

The remote monitoring system allows routine and regular detection, digital control, and eliminates complicated munual operation.

The protection requirement of SF double-deck tank is 1/10 of regular tanks, which greatly reduces the maintenance cost

SF double-layer tank is better used than regular tanks, which ensures the equipment efficiency and high cost performance.

SF double-layer tank is highly efficient and economical, has high environmental protection perfor mance, and can effectively protect energy, avoiding the serious harm and loss caused by energy leakage.

S&F Double-layer Tank

Get in touch for more information or to arrange a demo:

Products Category

Product Description

Product Introducticn

The main steel body of S&F Double-layer tank (with the full name of "steel reinforcedfiber-glass double-layer tank") is called "inner shell", and the FRP protective anddetecting layer

is called "outer shell".When S&F Double-layer tank is buried under.round,inner shell endures the pressure from earth and stone mainly. Although outerpressure acts on outer shell directly, it transfers to the inner shell synchronously.Therefore,the outer shell isn't the main part to keep the structural strength.

Standards for Product Implementation

♦ GB50156-2012 Design and construction standards of automobile gasotine and gas refueling station

♦ NB/T47003.1-2009 steel welded normal pressure vessel

♦ JB/T4709-2007 regulations of steel welded pressure vessel

♦ GB985-2008 Basic Forms and Sizes of Grooves for Arc Welding, Gas Welding and Gas Cutting

♦ JB4730-2005 Nondestructive Testing of pressure vessel

♦ UL-58

♦ UL-1476

Product Specification

|

Standard volume |

Diameter |

Tank length |

Anchor number |

Band number |

|

20 |

2400 |

5053 |

2 |

2 |

|

30 |

2400 |

7080 |

4 |

4 |

|

30 |

2600 |

6192 |

4 |

4 |

|

40 |

2600 |

8050 |

4 |

4 |

|

40 |

2800 |

7190 |

4 |

4 |

|

50 |

2600 |

10100 |

6 |

6 |

|

50 |

2800 |

8700 |

4 |

4 |

Product Structure

S&F double-wall product structure

Safety

Inner layer-double layer structure manufacturing, compared with the regular 5mm thickness single layer tank, the strength is greatly improved.

Outer layer- A reinforced glass fiber layer with a thickness exceeding 2.5m,featuring excellent crush and seismic resistance. It also has high corrosion resistance and electric erosion resistance.

Unique technology is used to create a 0.1m gap between the inner and outer layers and eliminate the hidden trouble from the root.

Advanced leaking detector 24-hour real-time monitoring to eliminate the hidden security risks caused by leakage.

Environmental Protection

Double-layer structure, with 0.1mm gap inside, the outer FRP ensures that the leakage material will not directly leak and pollute the soil and water.

The outer FRP will not cause electrolytic corrosion with groundwater,brine,etc.

The outer FRP will not corrode with gasoline,diesel oil and leaded gasoline.

Leak detectors provide 24/7 monitoring to eliminate potential pollution hazards.

Leaking detection system is easy to detect and maintain, protects the ecological environment of soil and water.

Effective protection of the environment, avoiding the high environmental protection cost.

Economy

The service life ofSF double-deck tank is 5-10 times of regular tanks, which can guar-antee safe service for at least 30 years.

Convenient installation greatly shortens the construction period and reduces cost input.

The remote monitoring system allows routine and regular detection, digital control, and eliminates complicated munual operation.

The protection requirement of SF double-deck tank is 1/10 of regular tanks, which greatly reduces the maintenance cost

SF double-layer tank is better used than regular tanks, which ensures the equipment efficiency and high cost performance.

SF double-layer tank is highly efficient and economical, has high environmental protection perfor mance, and can effectively protect energy, avoiding the serious harm and loss caused by energy leakage.

Get Product Information For Free

Note: Please leave your email address, our professionals will contact you as soon as possible!

Language

Language